Lithium-ion batteries are becoming more and more popular for forklift applications due to their numerous advantages, including being safer than other types of batteries. Forklift operators often require long operating hours, fast charging times, and reliable performance from their vehicles, making it essential to choose a battery that meets these needs while also being safe.

By using lithium-ion batteries, forklift operators can reduce the risks associated with using other types of batteries. Here are some of the reasons why lithium-ion batteries are safer for forklift applications:

Reduced Risk of Thermal Runaway

One of the key reasons why lithium-ion batteries are safer than other types of batteries is that they have built-in safety features that help regulate temperature. Lithium-ion batteries include thermal management systems that monitor and adjust the battery's temperature, which helps mitigate the risk of thermal runaway.

Thermal runaway is a condition where the battery can overheat and lead to a fire or explosion. This is a common issue with other types of batteries, such as lead-acid batteries. Lithium-ion batteries are much less likely to experience thermal runaway because of their thermal management systems and the fact that they do not rely on potentially hazardous chemicals like other batteries.

No Hazardous Materials

Another safety advantage of lithium-ion batteries is that they do not contain hazardous materials like other battery types do. Lead-acid batteries, for example, contain lead and other substances that can be harmful to the environment and human health.

By using lithium-ion batteries, forklift operators can avoid any risk of exposure to these hazardous materials. This is especially important since forklift batteries can be very large and difficult to handle, making them a potential hazard for anyone who comes into contact with them.

Lower Risk of Acid Spills

Another safety concern when using batteries for forklifts is the risk of acid spills. Lead-acid batteries can leak acid if they become damaged, which can be hazardous if not handled safely. Lithium-ion batteries do not have this risk, making them a safer choice for forklift operators.

No Gas Emissions

Lead-acid batteries emit gas during charging, which can be dangerous if not properly ventilated. By contrast, lithium-ion batteries do not produce gas during charging, making them a much safer choice. This also means that operators do not need to worry about ventilation when using lithium-ion batteries, which can make the battery installation process much easier.

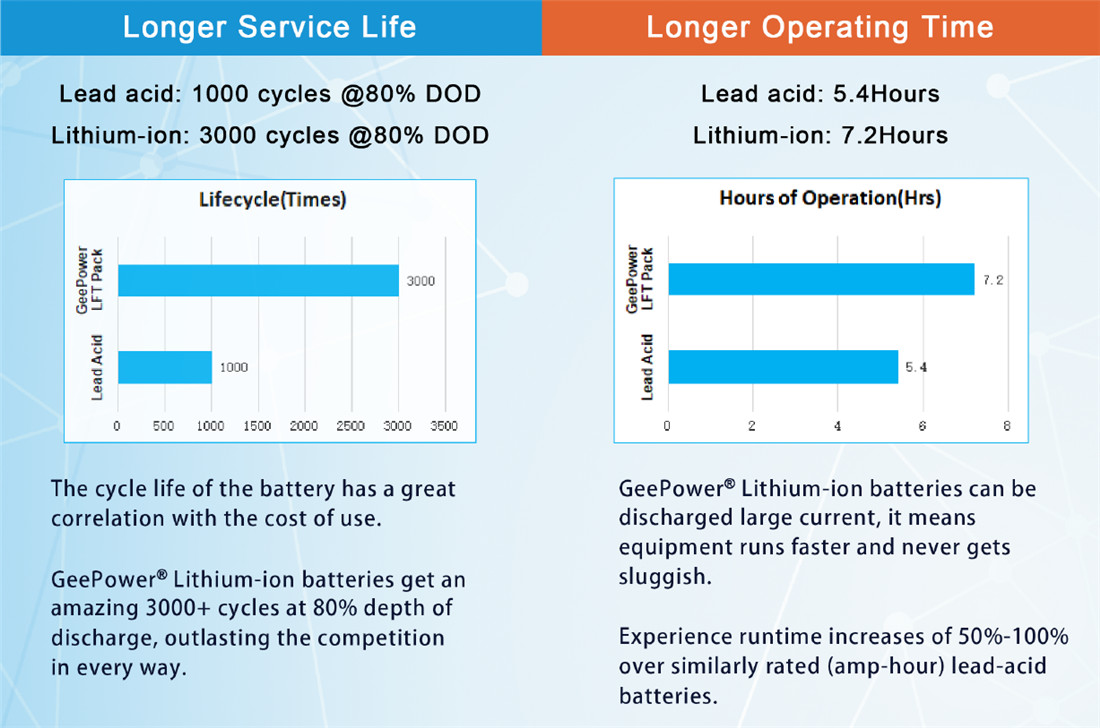

Longer Lifespan

Finally, another significant safety benefit of lithium-ion batteries is that they have a longer lifespan than other battery types. Lead-acid batteries, for example, typically last around four to five years, while lithium-ion batteries can last up to ten years or more. This longer lifespan means that forklift operators do not need to replace the batteries as frequently, reducing the risk of accidents and environmental impact associated with battery disposal.

In conclusion, lithium-ion batteries are a safer choice for forklift operators due to their built-in thermal management systems, lack of hazardous materials, lower risk of acid spills, no gas emissions, and longer lifespan. By choosing lithium-ion batteries for their forklifts, operators can reduce the risks associated with battery use and help keep their workplace safe for everyone.

Post time: Jun-02-2023