When it comes to choosing a cost-effective battery for your forklift truck, there are several factors to consider. The right battery can increase your forklift's uptime, reduce costs, and improve efficiency. Here are some tips to help you choose the right battery for your needs:

1. Capacity

Make sure you choose a battery with the right capacity to meet your forklift's energy requirements. The battery should be large enough to support the forklift's energy-hungry tasks, such as lifting and transporting heavy loads. Most manufacturers recommend choosing a battery with a 20-30% larger capacity than you currently need to ensure that the forklift can operate continuously for a full shift without the need for recharging.

2. Battery Chemistry

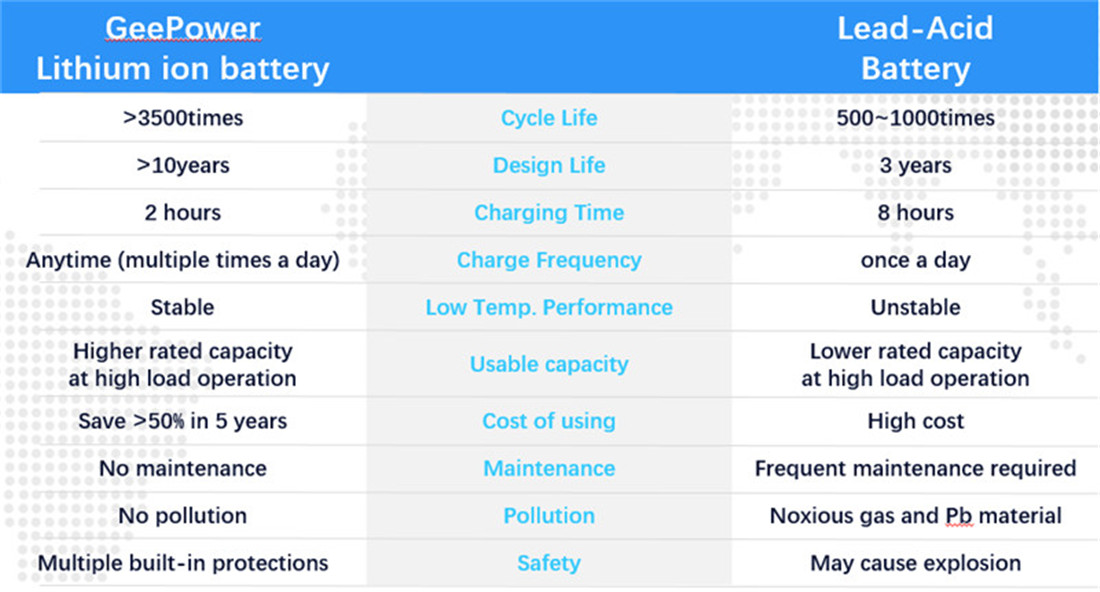

The battery chemistry you choose will affect the cost of the battery, as well as its performance and lifespan. The two most common battery chemistries used in forklifts are lead-acid and lithium-ion. Lead-acid batteries are less expensive upfront, but they require frequent maintenance, such as watering and cleaning. Lithium-ion batteries are more expensive upfront, but they have a longer lifespan, require less maintenance, and are more energy-efficient, which can lead to long-term cost savings.

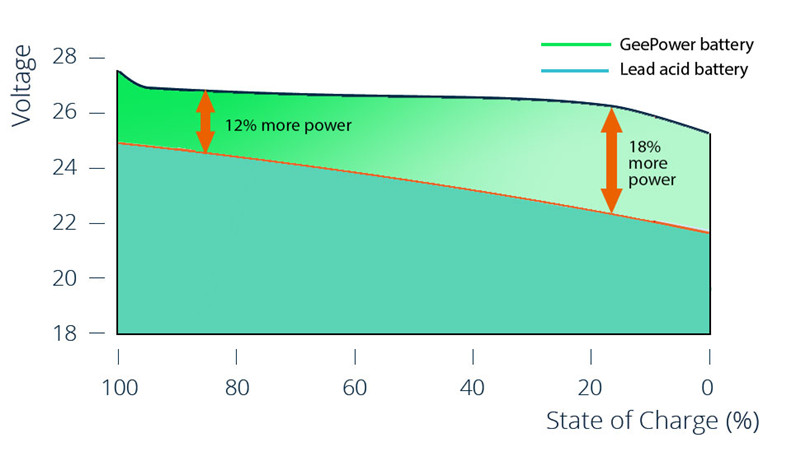

3. Voltage

Forklifts require batteries with a high voltage to provide enough power to lift heavy loads. To ensure compatibility with your forklift, check the manufacturer's specifications for the voltage requirements. Make sure the battery voltage is compatible with your forklift voltage, and that the battery can deliver the necessary current to run the forklift.

For each complete charge and discharge cycle, a lithium ion battery saves on average 12~18% energy. It can easily be multiplied by the total energy that can be stored in the battery and by the expected >3500 lifecycles. This gives you an idea of the total energy saved and its cost.

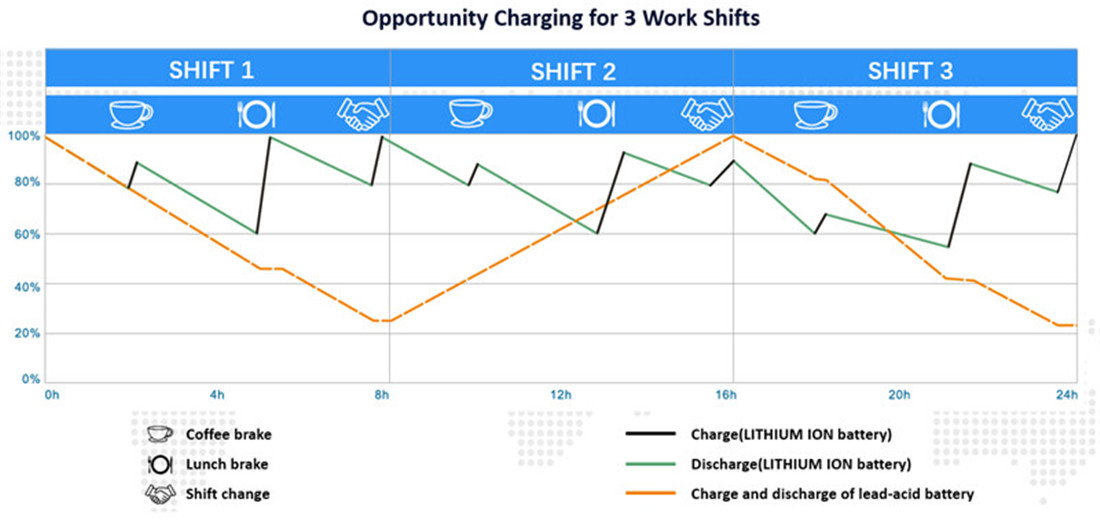

4. Charging Time

Consider the charging time of the battery when choosing a cost-effective forklift battery. A battery that can be charged quickly will reduce downtime and increase productivity. Lithium-ion batteries have faster charging times than lead-acid batteries, which can be a significant factor in increasing uptime and productivity. Make sure to choose a battery with the right charging time for your specific forklift and operating environment.

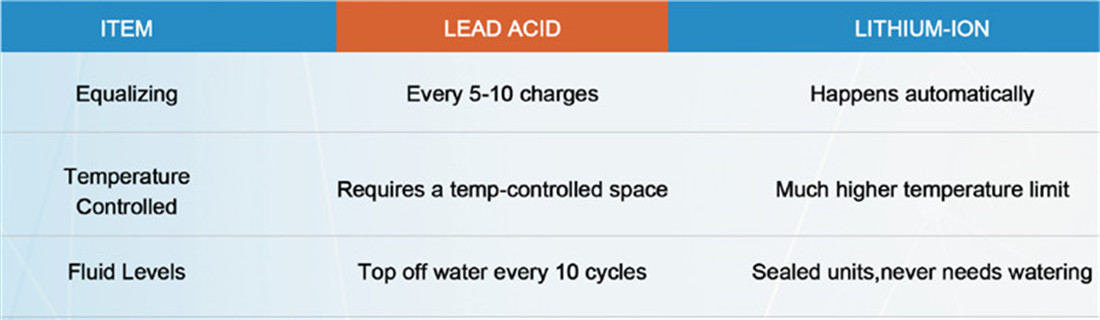

5. Maintenance Requirements

Different batteries have different maintenance requirements, which can impact the cost-effectiveness of the battery. Lead-acid batteries require regular maintenance, such as watering, cleaning, and equalizing. Lithium-ion batteries, on the other hand, require minimal maintenance, which can lead to long-term cost savings. Consider the cost and frequency of maintenance when selecting a battery for your forklift. Lithium-ion batteries may cost more upfront, but they have fewer maintenance requirements, which can lead to significant cost savings over time.

6. Total Cost of Ownership

When choosing a cost-effective battery for your forklift, you need to look beyond the initial purchase price of the battery. Consider the total cost of ownership over the battery's lifespan. This includes the cost of maintenance, replacement, charging, and any other associated costs. Lithium-ion batteries may have a higher initial cost, but they have a longer lifespan and require less maintenance, which can lead to long-term cost savings. On the other hand, lead-acid batteries have lower upfront costs but require more frequent replacement and maintenance, which can be more expensive in the long run.

In conclusion, choosing the most cost-effective battery for your forklift truck requires careful consideration of several factors such as capacity, voltage, charging time, battery chemistry, and maintenance requirements. Careful analysis of these factors will help you identify the right battery for your forklift that is both cost-effective and can meet your specific needs. Contact with GeePower to get the best battery solution for your forklift.

Post time: Jun-02-2023