PV Energy Storage System For Farmland Irrigation

What is PV Energy Storage System For Farmland Irrigation ?

The farmland irrigation photovoltaic energy storage system is a system that combines photovoltaic (PV) solar panels with energy storage technology to provide reliable and sustainable power for the farmland irrigation system. Photovoltaic solar panels use sunlight to generate electricity to power irrigation pumps and other equipment needed to water crops.

The energy storage component of the system can store excess energy generated during the day for use when sunlight is insufficient or at night, ensuring continuous and reliable power supply for the irrigation system. This helps reduce dependence on the grid or diesel generators, resulting in cost savings and environmental benefits.

Overall, photovoltaic energy storage systems for farmland irrigation can help farmers reduce energy costs, increase energy independence, and contribute to sustainable agricultural practices.

Battery System

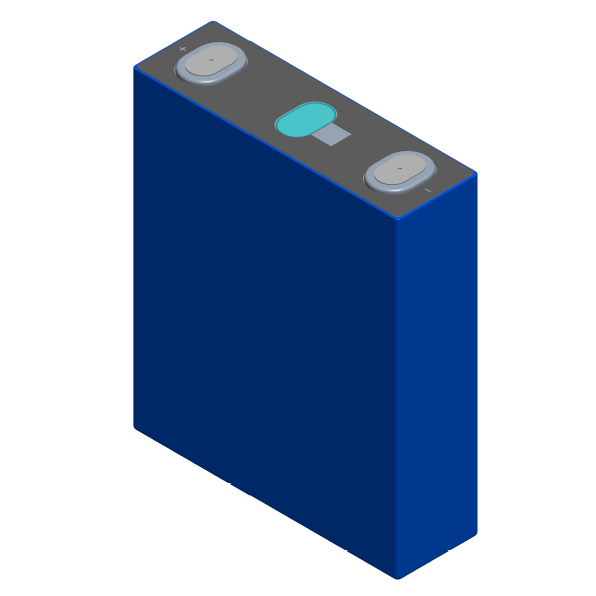

Battery Cell

Parameters

| Rated Voltage | 3.2V |

| Rated Capacity | 50Ah |

| Internal Resistance | ≤1.2mΩ |

| Rated working current | 25A(0.5C) |

| Max. charging voltage | 3.65V |

| Min. discharge voltage | 2.5V |

| Combination Standard | A. Capacity Difference≤1% B. Resistance()=0.9~1.0mΩ C. Current-maintaining Ability≥70% D. Voltage3.2~3.4V |

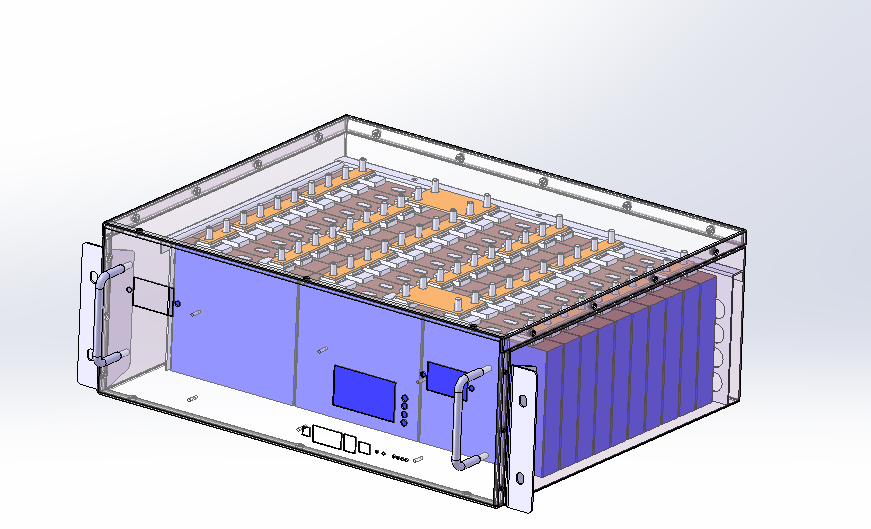

Battery Pack

Specification

| Nominal Voltage | 384V | ||

| Rated Capacity | 50Ah | ||

| Minimal Capacity(0.2C5A) | 50Ah | ||

| Combination Method | 120S1P | ||

| Max. Charge Voltage | 415V | ||

| Discharge cut-off voltage | 336V | ||

| Charge Current | 25A | ||

| Working Current | 50A | ||

| Maximum discharge current | 150A | ||

| Output and Input | P+(red) / P-(black) | ||

| Weight | Single 62Kg+/-2KgOverall 250Kg+/-15Kg | ||

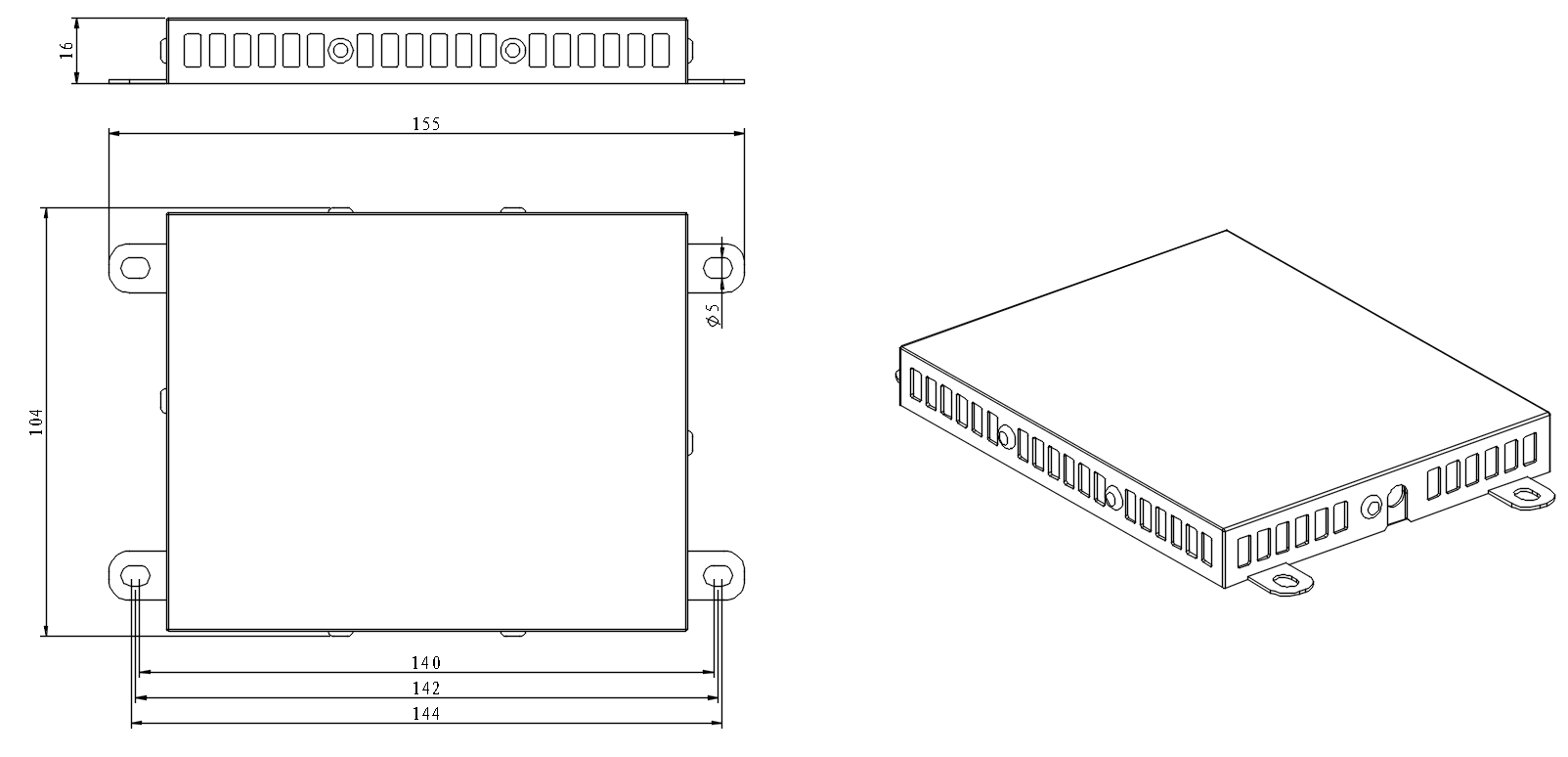

| Dimension(L×W×H) | 442×650×140mm(3U chassis)*4442×380×222mm(control box)*1 | ||

| Charge Method | Standard | 20A×5hrs | |

| Quick | 50A×2.5hrs. | ||

| Operating Temperature | Charge | -5℃~60℃ | |

| Discharge | -15℃~65℃ | ||

| Communication interface | R RS485RS232 | ||

Monitoring System

Display(touch screen):

- Intelligent IoT with ARM CPU as the core

- Frequency of 800MHz

- 7-inch TFT LCD display

- Resolution of 800*480

- Four-wire resistive touch screen

- Pre-installed with McgsPro configuration software

Parameters:

| Project TPC7022Nt | |||||

| Product Features | LCD screen | 7”TFT | Externalinterface | serial interface | Method 1: COM1(232), COM2(485), COM3(485)Method 2: COM1(232), COM9(422) |

| Backlight type | led | USB interface | 1XHost | ||

| Display color | 65536 | Ethernet port | 1X10/100M adaptive | ||

| Resolution | 800X480 | Environmental conditions | Operating temperature | 0℃~50℃ | |

| Display brightness | 250cd/m2 | Working humidity | 5%~90% (no condensation) | ||

| touch screen | Four-wire resistive | storage temperature | -10℃~60℃ | ||

| Input voltage | 24±20%VDC | Storage humidity | 5%~90% (no condensation) | ||

| rated power | 6W | Productspecifications | Case material | Engineering plastics | |

| processor | ARM800MHz | Shell color | industrial gray | ||

| Memory | 128M | physical dimension(mm) | 226x163 | ||

| System storage | 128M | Cabinet openings(mm) | 215X152 | ||

| Configuration Software | McgsPro | ProductCertificate | certified product | Comply with CE/FCC certificationstandards | |

| Wirelessextension | Wi-Fi interface | Wi-Fi IEEE802.11 b/g/n | Protection level | IP65(front panel) | |

| 4Ginterface | China Mobile/China Unicom/Telecom | Electromagnetic Compatibility | Industrial level three | ||

Display Interface Details:

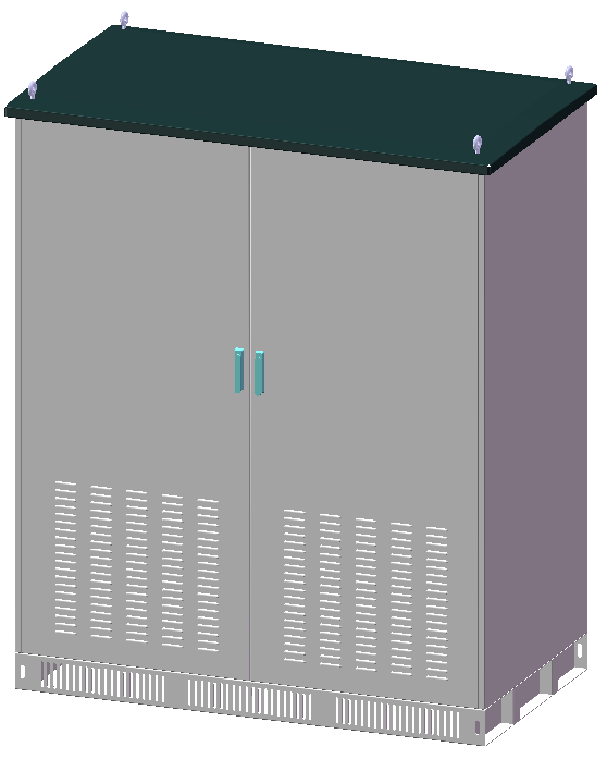

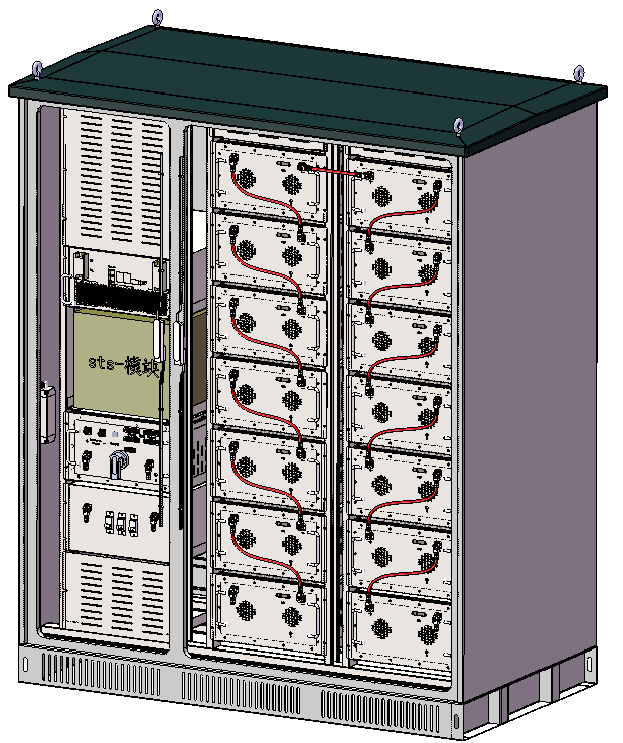

Product Apperance Design

Back View

Inside View

Heavy-Load Vector Frequency Converter

Introduction

The GPTK 500 series converter is a versatile and high-performance converter designed to control and adjust the speed and torque of three-phase AC asynchronous motors.

It utilizes advanced vector control technology to deliver low-speed, high-torque output.

Specification

| Item | Technical Specifications |

| Input Frequency Resolution | Digital Settings:0.01HzAnalogue Settings:Max frequency×0.025% |

| Control Mode | Sensorless Vector Control(SVC)V/F Control |

| Starting torque | 0.25Hz/150%(SVC) |

| Speed Range | 1:200(SVC) |

| Steady Speed Accuracy | ±0.5%(SVC) |

| Torque Increase | Automatic Torque Increase;Manual TorqueIncrease:0.1%~30%. |

| V/F Curve | Four Ways:Linear;Multipoint;FullV/Fseparation;Incomplete V/FSeparation. |

| Acceleration/Deceleration Curve | Linear or S-curve acceleration and deceleration; Four acceleration/deceleration times,timescale:0.0~6500s. |

| DC Brake | DC braking start frequency:0.00Hz~Max frequency;Braking time:0.0~36.0s;Braking action current value:0.0%~100%. |

| Inching Control | Inching frequency range:0.00Hz~50.00Hz; Inching acceleration/decelerationtime:0.0s~6500s. |

| Simple PLC、Multi-speedoperation | Up to 16 speeds via built-in plc or controlterminals |

| Built-in PID | Closed-loop control systems for process controlcan be easily realised |

| Automatic VoltageRegulator(AVR) | Can automatically keep the output voltageconstant when the grid voltage changes |

| Overpressure and overcurrent speed control | Automatic limitation of current and voltage during operation to prevent frequentover-current and over-voltage tripping. |

| Fast current limit function | Minimise overcurrent faults |

| Torque limiting and control of instantaneous non-stop | "Digger" feature, automatic limiting of torque during operation to prevent frequent overcurrent trips; vector control mode for torque control; Compensate for voltage drop during transient power failure by feeding energy back to the load, maintaining the inverter in continuousoperation for a short period of time |

Solar Photovoltaic MPPT Module

Introduction

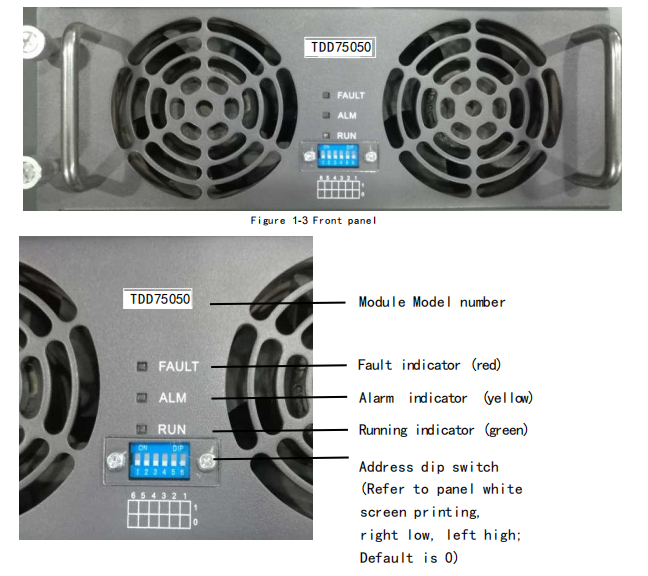

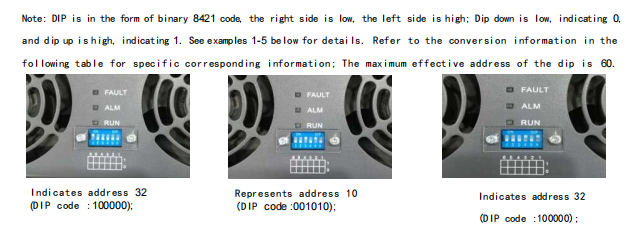

TDD75050 module is a DC/DC module specially developed for DC power supply, with high efficiency, high power density and other advantages.

Specification

| Category | Name | Parameters |

| DC Input | Rated voltage | 710Vdc |

| Input voltage range | 260Vdc~900Vdc | |

| DC Output | Voltage range | 150Vdc to 750Vdc |

| Current range | 0 ~ 50A (current limit point can be set) | |

| Rated current | 26A (required to set current limit point) | |

| Voltage stabilization accuracy | < ± 0.5% | |

| Steady flow accuracy | ≤± 1% (output load 20% ~ 100% rated range) | |

| Load adjustment rate | ≤± 0.5% | |

| Start the overshoot | ≤± 3% | |

| Noise Index | Peak-to-peak noise | ≤1% (150 to 750V, 0 to 20MHz) |

| Category | Name | Parameters |

| Others | Efficiency | ≥ 95.8%, @750V, 50% ~ 100% load current, rated 800V input |

| Standby power consumption | 9W (input voltage is 600Vdc) | |

| Instant impulse current at startup | < 38.5A | |

| Flow equalization | When the load is 10% ~ 100%, the current sharing error of the module is less than ± 5% of the rated output current | |

| Temperature coefficient (1/℃) | ≤± 0.01% | |

| Startup time (select the power- on mode through the monitoring module) | Normal power on mode: Time delay from DC power-on to module output ≤8s | |

| Output slow start: the start time can be set through the monitoring module, the default output start time is 3~8s | ||

| Noise | No more than 65dB (A) (away from 1m) | |

| Ground resistance | Ground resistance ≤0.1Ω, should be able to withstand current ≥25A | |

| Leakage current | Leakage current ≤3.5mA | |

| Insulation resistance | Insulation resistance ≥10MΩ between the DC input and output pair housing and between the DC input and DC output | |

| ROHS | R6 | |

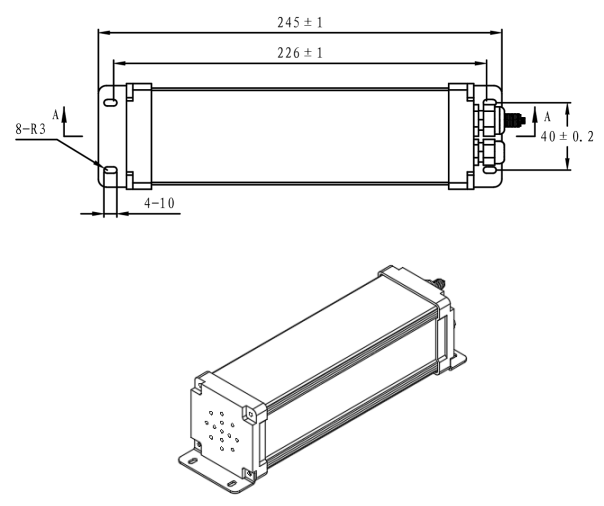

| Mechanical Parameters | Measurements | 84mm (height) x 226mm (width) x 395mm (depth) |

Inverter Galleon III-33 20K

Parameters

| Model Number | 10KL/10KLDual Input | 15KL/15KLDual Input | 20KL/20KLDual Input | 30KL/30KLDual Input | 40KL/40KLDual Input | |

| Capacity | 10KVA / 10KW | 15KVA / 15KW | 20KVA / 20KW | 30KVA / 30KW | 40KVA / 40KW | |

| Input | ||||||

| VoltageRange | Minimum conversion voltage | 110 VAC(Ph-N) ±3% at 50% load: 176VAC(Ph-N) ±3% at 100% load | ||||

| Minimum recovery voltage | Minimum conversion voltage +10V | |||||

| Maximum conversion voltage | 300 VAC(L-N)±3% at 50% load; 276VAC(L-N)±3% at 100% load | |||||

| Maximum recovery voltage | Maximum conversion voltage-10V | |||||

| Frequency Range | 46Hz ~ 54 Hz @ 50Hz system56Hz ~ 64 Hz @ 60Hz system | |||||

| Phase | 3 phases + neutral | |||||

| Power Factor | ≥0.99 at 100% load | |||||

| Output | ||||||

| Phase | 3 phases + neutral | |||||

| Output Voltage | 360/380/400/415VAC (Ph-Ph) | |||||

| 208*/220/230/240VAC (Ph-N) | ||||||

| AC Voltage accuracy | ± 1% | |||||

| Frequency range (synchronization range) | 46Hz ~ 54 Hz @ 50Hz system56Hz ~ 64 Hz @ 60Hz system | |||||

| Frequency range (battery mode) | 50Hz±0.1Hz or 60Hz±0.1Hz | |||||

| Overload | AC mode | 100%~110%:60 minutes;110%~125%:10 minutes;125%~150%:1 minute;>150%:immediately | ||||

| Battery mode | 100%~110%: 60 minutes; 110%~125%: 10 minutes; 125%~150%: 1 minute; >150%: immediately | |||||

| Current peak ratio | 3:1 (maximum) | |||||

| Harmonic distortion | ≦ 2 % @ 100% linear load; ≦ 5 % @ 100% nonlinear load | |||||

| Switching time | Mains power←→Battery | 0 ms | ||||

| Inverter←→Bypass | 0ms (phase lock failure, <4ms interrupt occurs) | |||||

| Inverter←→ECO | 0 ms (mains power lost, <10 ms) | |||||

| Efficiency | ||||||

| AC mode | 95.5% | |||||

| Battery mode | 94.5% | |||||

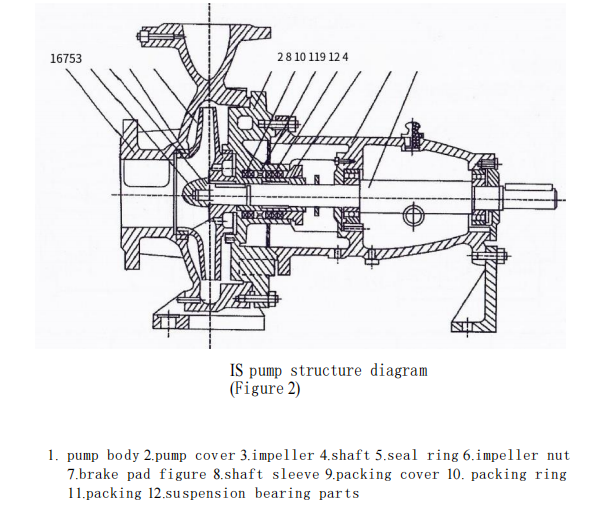

IS Water Pump

Introduction

IS Water Pump:

The IS series pump is a single-stage, single-suction centrifugal pump designed according to the international standard ISO2858.

It is used to transport clean water and other liquids with similar physical and chemical properties to clean water, with a temperature not exceeding 80°C.

IS Performance Range (Based on Design Points):

Speed: 2900r/min and 1450r/min Inlet Diameter: 50-200mm Flow Rate: 6.3-400 m³/h Head: 5-125m

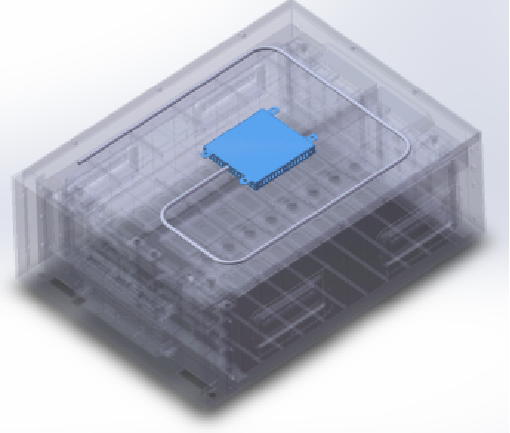

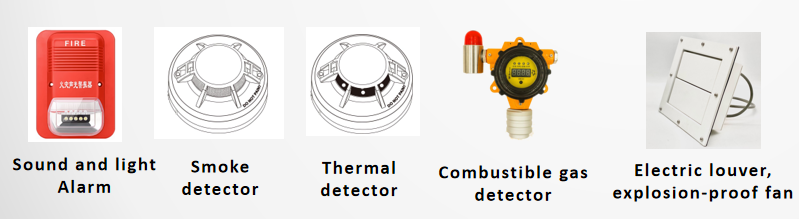

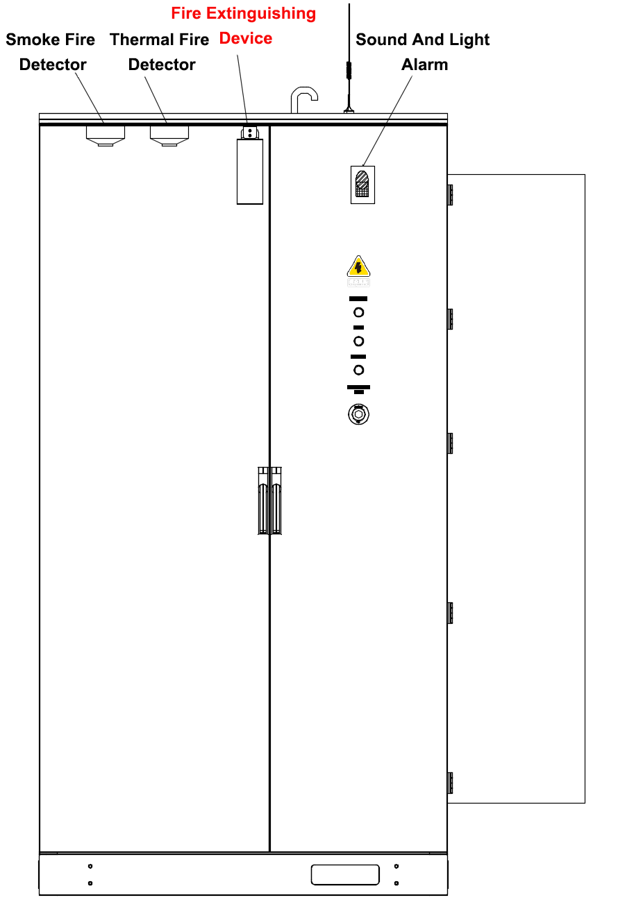

Fire Protection System

The overall energy storage cabinet can be divided into two separate protection areas.

The concept of "multi-level protection" is mainly to provide fire protection for the two separate protection areas and make the entire system act in association, which can truly put out the fire quickly.

And prevent it from re-igniting, ensuring the safety of the energy storage station.

The two separate protection zones:

- PACK level protection: The battery core is used as the source of fire, and the battery box is used as the protection unit.

- Cluster level protection: The battery box is used as the fire source and the battery cluster is used as the protection unit

Pack Level Protection

The hot aerosol fire extinguishing device is a new type of fire extinguishing device suitable for relatively enclosed spaces such as engine compartments and battery boxes.

When a fire occurs, if the temperature inside the enclosure reaches around 180°C or an open flame appears,

the heat-sensitive wire detects the fire immediately and activates the fire extinguishing device inside the enclosure, simultaneously outputting a feedback signal.

Cluster Level Protection

Rapid hot aerosol fire extinguishing device

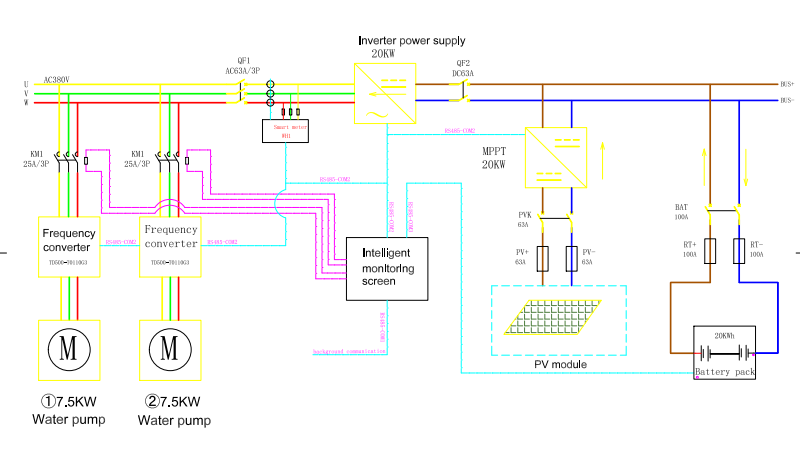

Electrical Schematic

The benefits of using photovoltaic energy storage systems for farmland irrigation are many and can have a significant impact on agricultural production.

Some key benefits include:

1. Cost savings: By harnessing solar energy and storing excess electricity, farmers can reduce their reliance on the grid or diesel generators, thereby lowering energy costs over time.

2. Energy independence: The system provides a reliable, sustainable source of power, reducing dependence on external energy suppliers and increasing the farm’s energy self-sufficiency.

3. Environmental sustainability: Solar energy is a clean, renewable energy that helps reduce greenhouse gas emissions and environmental impact compared to traditional energy sources.

4. Reliable water supply: Even when there is insufficient sunshine or at night, the system can ensure continuous power supply for irrigation, helping to maintain continuous water supply for crops.

5. Long-term investment: Installing a photovoltaic energy storage system can be a long-term investment, providing a reliable and sustainable source of energy for years to come, with the potential for good return on investment.

6. Government incentives: In many areas, there are government incentives, tax credits or rebates for installing renewable energy systems, which can further offset the initial investment cost.

Overall, photovoltaic energy storage systems for farm irrigation offer a range of advantages, including cost savings, energy independence, environmental sustainability and long-term reliability, making them an attractive option for modern agricultural operations.